Atwater Kent Model 206 (2nd Type) Restoration

|

The Atwater Kent Model 206 (2nd type) from about 1934 is a

6-tube AC Superhet with a tuned RF amplifier stage. It receives the

Broadcast, Police, and Short Wave bands. The schematic for the

model 206 (2nd type) can be found on-line at the Atwaterkent.info

web site in the Service

Manual. The schematic is NOT in the Riders Manuals nor is it online at

Nostalgiaair.org (these sources

only have the 1st type schematic).

The radio had seen minimal servicing in the past - all of the original parts

(except tubes) were still in place. I decided to try to maintain the

set in its original condition to the extent possible, yet get it working. However this vintage of AK receivers is difficult to

restore and maintain originality due to the unique cast end resistors and

deteriorating rubber covered wiring used. |

My

antique radio restoration logs

Condition As Found

This radio was purchased on eBay. The cabinet finish,

knobs, and grille cloth were original and in excellent condition. It was

stated in the auction that the radio would power up, but reception could not be

confirmed by the seller. There were no signs of any restoration seen in

the auction listing (although there were minimal photos). I always avoid knowingly purchasing a radio

that has been restored by a collector, as many collectors take shortcuts such as removing

the original capacitors and filters. In this case, the original filter

capacitors and all tube shields were still in place. The only evidence of

repair was a taped splice on the power cord. The chassis was very dirty, but

not rusty.

Previous Repairs

-

All but two tubes were branded RCA/Cunningham and were

engraved base types, and thus were likely the originals. The 80 and

one 58 had been replaced.

-

The power cord was original, but had been spliced and

taped. The power plug looked original (black bakelite or hard rubber)

but had some chips on the edges.

-

There was a piece of spaghetti tubing insulating the antenna

lead on one place where it was likely rubbing the chassis and shorting out.

Survey

My usual restoration procedure is to first make a complete

survey of the condition of all components. The survey results guide my

restoration strategy. I never apply power to a radio before

restoration, even through a "dim bulb tester" or variac "to see

if it works". If major and unique components are defective or

missing and

cannot be restored or replaced, I may elect to sell the radio for parts rather than restore it.

I always assume that all paper and electrolytic capacitors are leaky and thus should be

replaced (I always "restuff" the original containers if possible).

Any mica capacitors are assumed OK until testing proves otherwise.

-

The AC power switch was bad (it measured a high resistance) - dirty and/or oxidized contacts

were likely. It responded to a shot of Big Bath cleaner followed by

repeated cycling and then

worked correctly.

-

The speaker field was OK.

-

The speaker cone was perfect.

-

The output transformer was OK.

-

The power transformer checked out OK. My test procedure is to first

remove all tubes and apply about 10 volts through a fused variac and analog

wattmeter. I then check if the high voltage winding is balanced across

the center tap. An unbalance of more than about 1 volt indicates

possible shorted turns. I then raise the voltage gradually up to the

specified line voltage (110 volts) while monitoring the wattmeter. At

full voltage I check the voltage of all windings, and again check the high

voltage balance. Unloaded, a good transformer will draw less than 10

watts and each half of the high voltage should be equal within a few volts.

-

All RF coils and the IF transformers were OK.

-

All the tubes tested except the 2A6 tested good. The 2A6 tested weak

(470/750)-diodes OK. The 2A7 tube cap had come off and was found

inside the grid cap.

-

Some of the wiring in the radio was rubber covered and the insulation was falling

off. All of this damaged wiring would have to be replaced.

-

Most of the tin foil on the 2A6 cardboard tube shield was missing.

-

The plastic dial cover was missing

-

11 cast end fixed resistors were out of tolerance by more than 20%.

-

The tuning dial drive rubber was functional, but did slip somewhat.

Replacements are available from Adams Manufacturing.

-

Both dial lamps were burned out. These are 2.5 volt screw based (#41)

frosted type - not readily available.

-

The original power cord had been spliced, and the AC plug was chipped (not

sure if it was original). Both could likely be retained.

Repairs

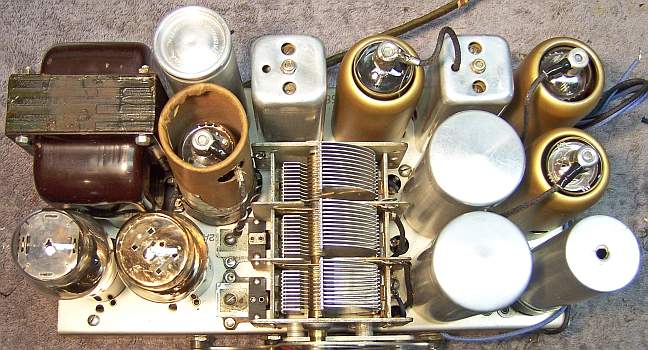

Before starting repairs I made BEFORE photos of the chassis top and bottom. I use these photos to ensure that replacement parts and

wiring are placed as close as possible to their original positions. Some

radios are subject to problems (such as oscillation) if wiring is re-routed or

lead dress is not the same as the original. The Service

Manual for

this radio fortunately had parts placement diagrams. And unlike original

AK documentation, parts values had been written in on the schematic. The

original documentation only contained AK part numbers - no values.

AK resistor color codes are unique and very non-standard. Servicing this radio is very difficult.

Most resistors are cast end dogbone type mounted on terminal strips in groups of

3 or 4. All the wiring in the area of the complex band switch is rubber

covered, and the insulation will fall off if disturbed! One must ensure

that this wiring is not disturbed during restoration, else a lot of work would be

required repair the damage.

All tubes and tube shields were removed. The tuning capacitor and dial

assembly was removed for cleaning and restoration of the tuner support grommets

and dial drive rubber.

The top and sides of the chassis was cleaned with GoJo hand cleaner and 00 steel

wool. Since this process may leave small steel wool fragments that can cause

problems later, I follow up with a thorough vacuuming and go over everything

with a small magnet and masking tape to pick up any stray fragments. I

continue to use steel wool as I have yet to find a substitute that does as good

a job removing the "gunk".

The tuning capacitor was cleaned in my old Heathkit ultrasonic clean (using

dilute

ammonia) followed by thorough rinsing and then cleaning with soap,

water, and toothbrushes. It was then dried using a heat gun. The

drive rubber on the tuning shaft was replaced using a part available from Adams

Manufacturing. The tuning capacitor grommets were replaced using

reproduction parts available from Renovated

Radios (part number GLg-Tuner). These grommets are slightly too thick,

so about 3/32" was trimmed from the thick side using a new single edge

razor blade (the center hole and outside diameter of these grommets is correct

for this radio). The trimmed side was installed on the top of the chassis,

with the now thicker side below.

Insulation breaks in the pilot lamp wiring were repaired using shrink tubing. The

power cord was also re-spliced and insulated at the splice using several layers

of shrink tubing. The original AC plug was cleaned up and reinstalled,

even with its chips. All damaged rubber wiring was replaced using cloth

covered wire of the appropriate color. I always use "unrated"

type wire available from RadioSupply.Com

(their 600 volt rated wire is not appropriate for radio restoration). The

antenna lead was especially difficult to replace, since it must attached to an

almost inaccessible lug on the band switch.

Capacitors

The original power supply filter capacitors were removed and restuffed.

The original filter capacitors were an 8mfd at 475 volt wet type capacitor

(C19), and a 3-section dry type capacitor (C18).

The

capacitor cans were chucked in my Unimat lathe and their cases scored about 1"

from the bottom. The cuts were then completed using a hobby razor saw and

the edges cleaned up using an Exacto knife. The original contents were then removed and the capacitor cases

cleaned inside and out. For the input filter C19 (a wet type) the original positive element was

removed, leaving the aluminum stud. The stud was then cut short, a hole

drilled, and a solder lug attached. The positive lead of a 10mfd/450 volt

capacitor was attached to the solder lug. The negative lead of the new capacitor was extended,

insulated, and then routed though a

small hole drilled into the capacitor base and wrapped around the threaded

portion of the capacitor case. This lead thus contacted the chassis when

the capacitor was mounted. The two halves of the case were then

joined together using a plumbing 3/4" PVC pipe coupling wrapped with

masking tape, and epoxied to each case half. The masking tape is needed

since the couplings are slightly too small in diameter. It also should

make it possible to disassemble the capacitor in the future should that be

necessary.

The 3-section filter C18 was rebuilt by drilling small holes next to each

terminal lug, plus one for the common ground lead near the edge of the

can. The original values were 4 and 8mfd at 450 volts and 10mfd at 25

volts. Replacement values used were 4.7 and 10mfd at 450 volts and 10mfd

at 50 volts. Their positive leads were extended using #22 buss wire and

insulated with spaghetti tubing. The bare buss wires were routed through

the drilled holes in the base and soldered to the original capacitor

terminals. The common ground lead was clamped between the capacitor body

and the mounting clamp. The two halves of the case were then

joined together using a plumbing 3/4" PVC pipe coupling as for C19 above.

All the mica and padder capacitors were left in place after testing for

leakage.

All the original Atwater Kent paper capacitors were rebuilt in their original cases

using modern 630 volt film capacitors in order to maintain the original

under-chassis appearance. Most single capacitors had radial leads,

the bottom capacitor in the photo below (although some had axial insulated

wire leads). My restuffing process is as follows:

- The original capacitor is removed from the radio, and the required lead

length noted.

- The low melting point wax from each end is melted and removed using an old

25 watt soldering iron.

- The "solder" which attaches the radial lead wires to the ends of

the foil roll is then melted and the lead wires freed. This stuff appears to

be some sort of low melting point metal rather than solder. Once the

lead wires are freed from the foil roll, the blob that is left is cut and

the lead wires (which have a spaghetti covering) are carefully

removed by pulling them through the holes in the outer tube.

- Any remaining metal and wax is then removed from each end using heat and

scraping.

- While the wax is still molten, a small screwdriver is pushed through the

center of the foil roll on one end, forcing out a center portion of the

paper-wax roll from the other end.

- The projecting center of the paper-wax roll is then pulled with pliers and

essentially the foil is unrolled from the center out. One must be

careful not to break the foil roll! If that happens, you will have to

dig inside the foil using an Exacto knife until you can again grab the foil

with needle nose pliers.

- Once enough of the original foil is removed to allow room for the

replacement film capacitor, the replacement is wrapped in a narrow strip of

paper towel in order to keep the new capacitor from falling out.

- Radial lead wires are then covered with a piece of small spaghetti tubing

about 1/2" long and are inserted through the original holes in the

capacitor's cover (some original capacitors did not have this spaghetti).

- The lead wires are then attached to the replacement capacitor's leads and

soldered (a small loop is formed in the end of the new lead wire, which is

placed over the lead of the replacement capacitor). Any excess lead

length on the replacement capacitor is then cut off.

- The finished capacitor is then sealed with melted rosin (salvaged from RCA

catacombs, and also donated by members on Antique

Radio Forums).

Below are typical Atwater Kent

capacitors that have been restuffed with modern components. In the AK206,

only one capacitor C14 is a dual unit (the tone control capacitor) - the rest are

all singles.

The line bypass capacitor C20, 0.01mfd at 400 volts, was a problem. The

original was a metal clad unit with terminals on each end. It was mounted

using a clamp. It was leaky and had to be replaced. There was no

room inside the original case to mount a new film capacitor. The case was

opened and the original contents removed. A 0.01mfd/630 volt film

capacitor was mounted below the original where it is hidden. Its leads

were attached to the original's terminals.

Resistors

There were 11 cast-end resistors that needed replacement. Wattage

ranged from 1/3 to 2 watts. Most were 1/3 watt units. Several

strategies were used to replace these resistors in order to retain the original

under chassis appearance.

- R15, a 20K 2 watt unit did not have cast ends, and looked like a normal

dogbone resistor with leads wrapped around the ends. It was replaced

using a 20K 2 watt dogbone (measured 22K) painted black with silver ends,

like the original.

- R17, a 500 ohm 1 watt cast end resistor was replaced using an old style

500 ohm 1 watt carbon composition resistor (fatter and longer than today's 1

watt resistors) which was the same diameter as the original resistor.

The original resistor body was crushed and removed from the end caps.

One end could be pulled out. The other end was removed by crushing the

porcelain and digging out the pieces using a variety of tools. Small

holes were drilled in the center of each end cap. The inside of each

cap was enlarged slightly using a sharp Exacto knife with a #11 blade.

The leads of the resistor were passed through the drilled holes, and the

resistor body attached to the end caps using Epoxy cement. The

original resistor's radial leads were clipped off flush to the end caps, and

the resistor leads used to mount the resistor. The resistor body was

painted flat white, and then the appropriate stripes added using Hobby

enamel paint.

- In a few cases, I had salvaged cast end dogbone resistors that were within

tolerance. I collect used dogbone and AK cast end resistors, and

never throw one away!

- In several other cases, I had salvaged cast end dogbone resistors that had

drifted to within tolerance. These were repainted with the correct AK

color code using Hobby paint.

- In one case, I attempted to cast a reproduction using a mold fabricated

from Putty Epoxy. This did not turn out very well, so this was

abandoned (one was actually used).

- For several of the smallest 1/3 watt resistors, I used a normal 1/2 watt

carbon resistor for the body. The original resistor body was removed

and holes drilled in the end caps. The body of the replacement

resistor was painted the correct color code using Hobby paint, and its leads

passed through the end caps and attached to the original radial leads.

The resistor was not actually attached to the end caps, but was placed close

as possible. The resulting resistor was slightly shorter than the

original, but looks OK.

Dial Lamps

The dial lamps were originally 2.5 volt screw based FROSTED

bulbs. I could find no sources for replacements. So the alternative

was to use standard clear #41 bulbs (2.5 volts, 0.5 amps, screw based) and find

a way to frost them. I posed this question on Antique

Radio Forums, and got several good suggestions. Suggestions included

using frosted glass paint, candle wax, wood glue, and sanding with emory

paper. I first tried sanding the bulb with emory paper while chucked in my

small Unimat lathe. It seemed to work great! But when I proceeded to

install the bulbs in their sockets, both snapped off near the base! I

suppose the sanding weakened the bulb too much. Next I tried applying two

coats of standard wood glue using a small brush, allowing them to dry between

coats. This seemed to work well enough and provided some needed diffusion.

Cabinet

The cabinet needed a good vacuuming inside and then cleaning on the

outside with GoJo and 00 steel wool. No further treatment was needed.

A new dial cover was fabricated using a kit sold by Bill Turner on Dialcover.com.

Bill's web site also has the instructions for making a replacement dial cover.

Testing and Alignment

Once the radio chassis was reassembled and the tubes installed, power was brought up

slowly using a variac. AC power consumption was monitored using a watt meter, and a

DVM monitored the B+. The radio came to life immediately and worked

well. The radio was then aligned using the instructions in the Service

Manual. The radio is quite sensitive, and also has very good tone due

to the large electrodynamic speaker and solid cabinet. I left the original

(weak) 2A6 tube in place - I doubt if a new tube would make any significant

difference in performance.

Restoration Results

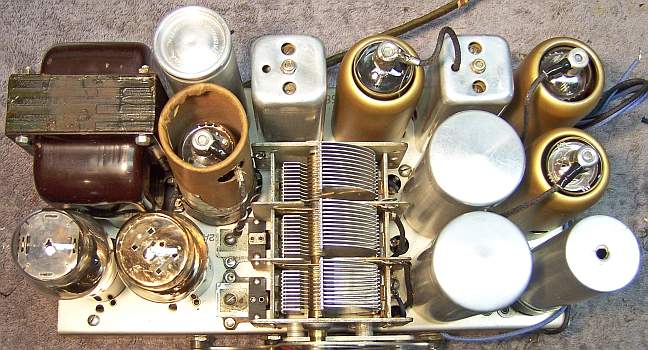

Chassis Bottom Before and After Restoration