Sparton Model 67 Restoration

My

antique radio restoration logs

There was no model number or any other information located anywhere on

the radio. The radio was identified by looking through Riders manuals for

Sparton radios with the same tube complement - there were several

possibilities. The model number was then identified by comparing the part

number of the speaker in the radio with the one specified in Riders parts list

for the model 67. Riders also had a chassis photo which exactly matched my

radio. Still, I cannot be sure that my radio is a Sparton model 67 or is another Sparton with the same chassis.

|

The 1934 Sparton model 67 is a conventional 6-tube

superhet that receives the

broadcast band and one short wave band The short wave band is

calibrated in METERS rather than megahertz - very unusual. The

radio has a tuned RF amplifier and uses 6.3 volt standard base tubes, typical of the early

1930's. The build quality is quite high.

The radio had seen extensive servicing in the past, with many original

components replaced. However I

decided to try and restore the original top and bottom chassis appearance as

much as possible.

The schematic and parts list for the radio can be found on Nostalgia

Air. |

Survey

My usual restoration procedure is to first make a complete

survey of the condition of all components. The survey results guide my

restoration strategy. If major and unique components are defective and

cannot be restored or replaced, I may elect to sell the radio rather than restore it.

When beginning a restoration project I assume that all paper and electrolytic capacitors are leaky and thus should be

replaced (I always "restuff" the original components if possible).

And I assume that most original resistors would have drifted and be out of tolerance range.

-

A type 85 tube had been installed to replace a 75 (not a

good replacement). The 6A7 tube was slightly weak. The remaining

tubes were all good. All were either RCA or Cunningham brand, and

likely the originals except for the 85.

-

The original can type filter capacitor block had been

removed and replaced by a dual tubular filter sticking through the original

filter chassis mounting hole! (fair enough - there is VERY little room under

the chassis).

-

Seven of the original paper-wax capacitors had been

replaced. Most of the original remaining Aerovox parts were mounted

with clamps riveted to the chassis. Some empty chassis rivet holes indicated

that many of the removed capacitors also had been mounted in this

fashion. Most replacement parts were not even close to the correct

values, and there were also some connection errors found later.

-

The power transformer was OK (very low wattage at no load,

and balanced high voltage windings).

-

The speaker field coil was OPEN, but the output transformer and

speaker cone were OK.

-

All RF coils and IF transformers were OK.

-

The original power cord and plug was usable.

-

The power switch on the volume control was defective but likely

only needed

cleaning.

-

Eight original resistors were out of tolerance

by 30-100%. One flexible wire wound unit was burned.

-

The speaker leads were cracked and frayed, and had been cut,

spliced back together, and taped. All the remaining wiring in the

radio was OK.

-

The dial drive shaft was bent and also frozen. The

speed reduction mechanism did not work.

-

Three knobs were missing - one original remained

(fortunately for matching purposes).

-

The dial cover glass had been replaced by a convex piece

marked Pyrex (and was the wrong size).

-

The tuning capacitor rubber grommets had deteriorated.

Cleaning

I normally clean the chassis before starting restoration.

I first blew off the above and below chassis dust with an air compressor.

The chassis was then partially disassembled for access and cleaning. The

tuning capacitor and dial drive mechanism was removed as a unit after

unsoldering the signal leads and ground braids. All the non-original

capacitors were then removed for access and restoration.

|

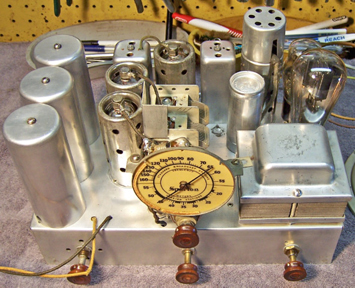

Here is the chassis with all non-original parts

removed. |

The chassis and top components were then cleaned using GoJo, steel wool, and

various brushes. The tuning capacitor was removed and then was cleaned with soap,

water, and toothbrushes and then dried using a heat gun and then lubricated.

Repairs

Speaker Field

Before doing any repairs or investing $$$ in any missing knobs, I had to determine if

the speaker field, which was open, could be repaired or if the speaker could be

replaced by a suitable PM type speaker. Fortunately, the construction of the speaker was such that the

field coil assembly was attached to the speaker basket using bolts and thus was removable. The field

coil connections to the speaker's terminal board were removed, the cover

unbolted, and the cover and speaker field removed.

The news was not good. About 1/4 of one side of the field coil bobbin was burned

away, and the winding exposed. I carefully removed the burned and charred cardboard. It appeared that what happened was that the insulation on the wire

leading to the inside of the field coil had failed, and that the

wire had arced to hot end of the field coil. This burned away part

of the coil bobbin. A short stub of the winding remained sticking out of

the inside (start) of the coil. Unbelievably, there was continuity between

this wire and the outside of the coil!

I was able to splice a new lead (fine magnet wire) to this stub, insulate it using electrical

tape, and reattach it to the original wire lead. I then cut a new piece of

fiber to replace the damaged outside of the coil. The field coil was then

reassembled. It measured about 900 ohms (the schematic said 1600 ohms).

The remaining problem was centering the cone, since the field pole piece had

been removed to gain access to the field coil. If first tried using paper

shims between the voice coil and the pole piece. The retaining bolts were

then tightened. When the shims were removed, the voice coil was dragging

on the pole piece - it was not centered correctly. After several failed

attempts, I achieved success by slightly loosening the attachment bolts and then

striking the field coil housing with a plastic faced hammer to move it in a

direction away from the side where the voice coil was dragging.

Eventually, the voice coil was properly centered and did not drag. The

speaker was tested by attaching it to a field DC power supply and a radio before

proceeding with the repairs. It worked well and sounded good.

Paper Capacitors

The original Aerovox capacitors remaining were all restuffed. All

except two were originally installed using clamps. One clamp was soldered

to a terminal strip, but the rest were riveted to the chassis. The rivets

were drilled out, the capacitors restuffed, and the capacitors reinstalled using

screws and nuts. All capacitors had crimped ends rather than being sealed

with wax. One end of the crimp was cut off near the end with a razor blade

and the contents removed after heating with a heat gun. The cardboard

discs on each end were saved. On one end, the crimp remained so the

cardboard disc was reinstalled and the new replacement capacitor threaded

through the hole in that end. I used strips of paper towel wrapped around

the new capacitor to center and secure it inside the case. I then melted some rosin (discarded RCA

catacomb potting compound) and poured it into the opposite end. The

remaining cardboard disc was then slipped over the other end of the replacement

capacitor. It was held in place by the rosin (if rosin is not

available, one could use hot melt glue colored with hobby paint to reseal the

capacitors). In some cases the original leads were longer than those of the

replacement part. In this case, I spliced on new buss wire near the case

of the capacitor so that the splice was concealed inside the capacitor case

after resealing.

Main Filter Capacitor Replacement

The original filter capacitor (8+8mfd), a screw mount can type, was

missing. I replaced it with a similar screw mount can from my junk

box. I do not know if the original capacitor had terminal lugs or wire

leads. In any case, the replacement had wire leads. I cleaned out

the contents and restuffed this can using two 10mfd 450 volt electrolytics.

The common ground buss wire lead was passed through a hole in the base of the

capacitor, through the mounting hole, and soldered to a ground point on the

chassis. Most of this lead was hidden.

Resistor Replacement

There were two defective flexible wire wound resistors. For the type 42

audio output tube cathode bias resistor (500 ohms), I found a suitable

replacement in my junk box! The 6A7 cathode resistor was about 30%

high. Since I did not have a suitable replacement, I replaced this

resistor with a 1-watt carbon resistor inside the original

spaghetti tubing, which hid the modern component nicely.

There were six dogbone type resistors that were more than 20% out of

tolerance. These are replaced with dogbone type resistors as were

used originally. I picked out NOS and used dogbone resistors from my stock

and junk box that were close to the correct needed resistance (within +/- 20%) and then

repainted them to match the original resistor's color codes using hobby paint.

The replacements may continue to drift, as would most new carbon composition

type resistors. But to me, maintaining the original look is more important

than long term reliability of the radio.

The radio also used a third type of resistor that I have never seen

before. They are unmarked as to brand, and are about the same size as a

1/2 watt carbon composition resistor.

Since I had no practical way of reproducing these, and no replacement stock,

I decided to replace them with dogbone type resistors, since the radio also had

dogbone types installed.

Volume Control Repairs

The volume control was removed, disassembled, and the switch and resistance

element cleaned using "Big Bath" cleaner. The switch worked well

after cleaning, but later failed during testing. Sometimes the radio would

not turn off! So I had to replace the volume control.

Other Repairs

- The tuning drive mechanism was originally frozen and the knob shaft was

bend. The unit was removed from the radio, disassembled, and cleaned

using lacquer thinner and various brushes. I eventually was able to

free the shaft and bearing. I then carefully clamped the shaft in a

large vice and attempted to straighten the shaft. I was not able to

get it completely straight, but it did eventually work. Originally

there was a spring brass spacer washer between the two halves of the

unit. But when that was installed, there was too much slip and the

unit would not drive the tuning capacitor. I suppose this was due to

wear. After removing the spacer washer, the unit operated smoothly

(except for the small wobble in the knob staft!)

- David Frush (parts2many at AOL dot COM) was able to provide the three

missing wooden knobs

- The tuning capacitor rubber bushings were replaced using ordinary rubber

grommets. They worked, but of course were much stiffer than the

originals.

- A type 75 tube was installed in place of the incorrect type 85 tube.

A NOS type 6A7 tube was installed to replace the weak first detector

tube.

- The bandswitch was cleaned using Big Bath spray.

- The frayed and taped speaker leads were removed and replaced with new

wires.

- A new convex dial glass of the proper size was ordered from TimeSavers.com

Testing

After the radio was completely reassembled, power was applied through a

wattmeter and fused Variac. Power was brought up slowly while monitoring

the B+ voltage. Normal B+ was reached with only 100 volts applied, and the

radio worked. I assume that the high B+ was due to my using a 10mfd input

filter capacitor instead of the 8mfd originally used. At 110 volts AC

input, the B+ was 325 volts! At normal 120 volt (or higher) input, the B+

would be extremely excessive. I rechecked the power transformer voltages,

and the AC voltages were normal under load. I then remembered the field

coil problem - it measured only 900+ ohms, but the schematic called for 1600

ohms. So the field coil, although it worked, likely had some shorted

turns. After some experimentation, I installed a 1500 ohm 10 watt power

resistor in series with the field coil. This lowered the B+ to 325 volts

with 120 volts in, and the radio still worked well. I also installed a

CL90 surge suppressor in series with the AC line to reduce the cold starting

surge.

The radio was then aligned and all adjustments were already very close to

correct. It performs very well - it has excellent

sensitivity (due to the tuned RF stage) and good tone also.

|

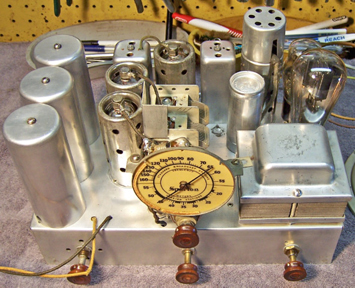

Chassis before restoration |

Chassis after restoration |

|

|

|

Restored Chassis |

Cabinet Rear |

|

|